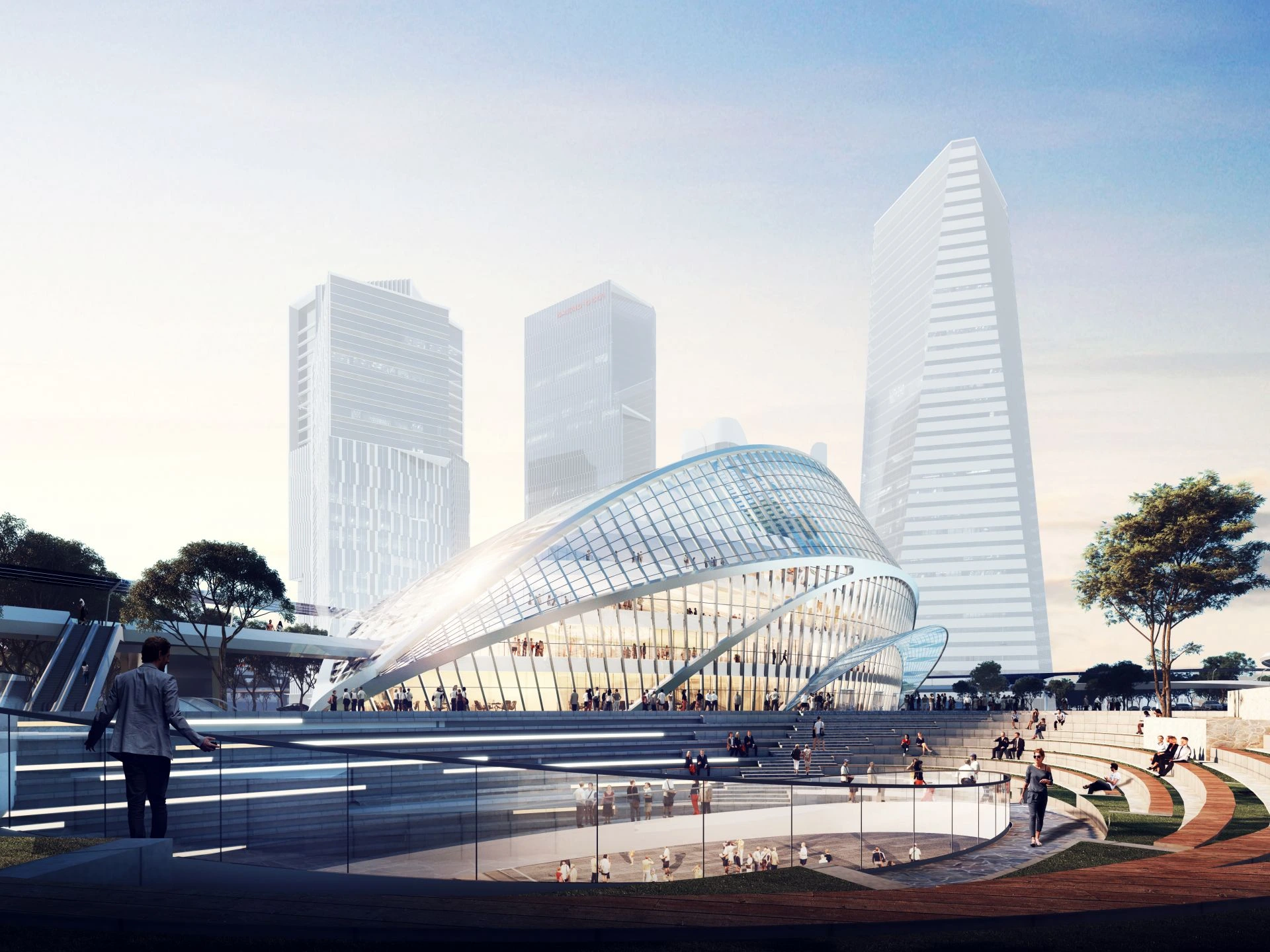

Qingdao Cruise Port Underground Space Project

Qingdao Cruise Port Underground Space Project: The "Underground Code" Activating Port Potential

Harbor Revival | Pioneer "Elite Force"

Project Overview

The Qingdao Cruise Port Underground Space Steel Structure Project uses high-strength steel as the core building material to construct the load-bearing framework and support system of the underground space. Through precise component prefabrication, modular assembly, and high-precision welding technology, it balances structural stability and space utilization. It not only bears the load requirements of multiple functions such as underground transportation hubs and commercial supporting facilities but also forms an organic connection with the above-ground cruise port buildings. With the tenacious characteristics of steel, it builds a "hardcore foundation" for the safe and efficient operation of this three-dimensional urban space, becoming a key structural support for connecting land and sea resources and activating the vitality of the port area.

Project Challenges and Solutions

Confined Construction Environment in Underground Space

Challenge: Dense underground structures, narrow working surfaces, and the need to coordinate spatial relationships with surrounding pipelines and pile foundations simultaneously, making traditional hoisting and welding operations significantly more difficult.

Solution: Adopted BIM technology for full-process simulation to pre-plan component hoisting paths and welding stations; implemented a factory prefabrication + on-site modular assembly model, with over 80% of steel structure components precisely processed in the factory, and only bolt connections used for on-site assembly, greatly reducing underground operation time and space occupation.

Anti-corrosion and Durability Requirements for Steel Structures

Challenge: The high-humidity underground environment is prone to steel corrosion, and the structure needs to meet the 100-year service life standard, making anti-corrosion treatment crucial.

Solution: Innovatively adopted a "arc spray aluminum + closed coating" dual anti-corrosion process, forming a dense metal protective layer on the steel surface. Combined with the partial application of weathering steel, the anti-corrosion life is extended to more than 30 years; meanwhile, long-term monitoring sensors are installed at key nodes to track corrosion data in real-time, achieving dynamic maintenance.

Stability Control of Long-span Structures

Challenge: Some areas of the underground hub adopt long-span steel structures (with a maximum span of 35 meters), which need to balance the self-weight load and additional stress from ground transportation and cruise port operations.

Solution: Optimized the structural mechanical model through finite element analysis, using box-section composite components to disperse stress; installed adjustable shock-absorbing devices at support nodes to absorb vibration loads; conducted synchronous stress monitoring during construction, offsetting part of the deformation through pre-tensioning technology to ensure long-term structural stability.

Technical Highlights

- Customized Application of High-performance Steel: For the underground humid environment and long-span load-bearing requirements, Q690D low-alloy high-strength steel is used as the main load-bearing component, with a yield strength of 690MPa, which is more than 50% higher than conventional steel. While reducing the cross-sectional size of components (reducing material usage by 20%), it meets impact and fatigue resistance requirements; weathering steel Q355NH is used at key nodes, forming a dense oxide layer through alloying elements such as Cu and Cr, improving natural anti-corrosion performance by 3 times and reducing later maintenance costs.

- Intelligent Processing Technology for Modular Components: Innovated "numerical control cutting + robotic welding" integrated technology to achieve fully automatic processing of complex components such as box sections and H-beams: laser cutting accuracy is controlled within ±0.5mm, the weld penetration uniformity of robotic welding reaches 98%, and the weld quality meets Grade I standard in GB/T 11345; through the component QR code traceability system, processing parameters and quality inspection reports are real-time associated with the BIM model, achieving full-chain traceability from "production - transportation - installation".

- Innovative Design of Steel Structure Nodes: Developed "rigid connection + flexible energy dissipation" composite nodes: the main structure adopts high-strength bolt friction-type connections to ensure reliable force transmission; in seismic load-sensitive areas, nodes are built with lead-core rubber pads, absorbing energy through rubber deformation and lead core yielding, improving the seismic performance of nodes to the 8-degree fortification standard; meanwhile, the node surface adopts arc transition design to reduce stress concentration and extend the fatigue life of the structure.

Related Success Cases

Qingdao Zhongrui Logistics Equipment Co., Ltd. Workshop Project

Advanced logistics equipment workshop, efficient production, strict quality control, National Gold Award

Qingdao Soda Ash Co., Ltd. Input Belt Project

Efficient operation of the input belt project, ensuring stable supply of soda ash raw materials

Qingdao World Trade Convention and Exhibition Center

50-meter long-span steel structure convention and exhibition center project